17

Aug 2016

Wrist Watches Factory Inspection

Good Morning Everyone!

Ever heard the saying “clock watchers never seem to be having a good time”?

Clearly, the One that said that never went on a wrist watches factory inspection! Let me tell you more about this!

WHERE: Shenzhen, Guangdong Province

WHEN: August 15th

WHAT: Wrist Watches

SBE TEAM: Jason – Engineer, Valentina, Teodora and Ade – Interns

Our journey started at Huangbeiling Station and it took almost 45 minutes to get to Qinghu Station at the end of the Red Line.

By the time we arrived, Jason was already there waiting for us with the Owner of the factory we were going to inspect.

Other 15 minutes ride by car in the crazy Chinese traffic – apparently Chinese have their own road code – until we finally reached the factory.

It was our first visit to a Chinese manufacturer but we were ready: anonymous building in a neglected area surrounded by workers’ apartments.

That was indeed a completely different environment from the ones we are used to in Europe but meeting and facing different realities it’s part of travelling and living in foreign Countries and every experience enriches you in the long run.

This unpleasant first impact did not discourage us: we were ready and excited for our first experience on field!

We have been welcomed with a quick tour of the work place, we saw the employees responsible for the assembly and the packaging.

After this we settled in a big meeting room and the Lady from the reception served us Oolong Tea.. a little treat before starting to work!

As soon as we finished our tea, the room has been filled with carton boxes with 100 pieces each and then the real inspection began.

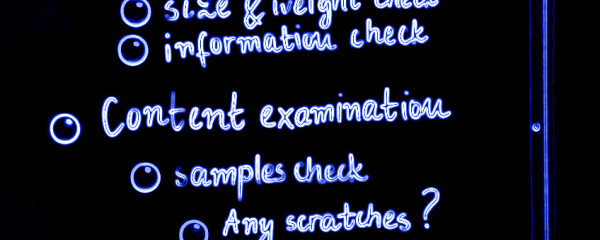

An inspection involves many matters that must be assessed carefully in order to deliver the best service to our customer.

In order:

- Supplier overview

- Quantity check

- Packing details

- Appearance attributes

- Functional attributes

- Labels & marks artwork

- Packing and markings

- Tests and Measurements

While leaving technical measurements to Jason, the main task for us Interns has been the appearance and attributes check.

Math Facts:

ORDERED QUANTITY: 112.200

FINISHED WATCHES: 94.400

NUMBER OF ITEMS: 6 Models

For this inspection we randomly sampled 315 pieces per item which means we inspected almost 2000 watches!

Not bad for our first time!

Want to know more about inspections?

Visit www.sbeinspection.com