02

Mar 2016

CHINA MANUFACTURE: HUMAN VS ROBOT

We’ve heard so many news regarding labor problem in China. China’s population is big and people need work for their life. Lately, many companies have turned their face to replace human with robot. Talking about cost, defect, and other things, yes, robot works more effectively more than human. But, what about human’s fate? How does automation change China manufacture industry?

Chinese workers are taking a nap

The Machine Effect

Human. We are created with emotion, intellectuality, health and other things that support our existence. It’s normal when we, as human work, there are times when we feel bored with what we do, or there are times when we get sick and we cannot do our works, right? How about robot? No bored, no sick, small chance of defect, consistent outcomes. Well…..

There’s a factory in DongGuan city, GuangDong province (home for China manufacture) which aims to use 1,000 robotic arms to automate 80% of its manufacturing by 2017. This factory is among of more than 1,000 manufacturers that have adopted robots to reduce their heavy reliance on labor in Dongguan.

This move toward automation strategy has been a major government’s agenda. It is the core of China manufacture agende “Made in China 2025” plan to upgrade its industry.

Home for China’s Industry

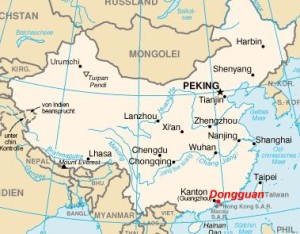

Dongguan city map

Chinese government’s agenda for Dongguan city is for this city to become a avant-garde of China’s robotics industry and an advanced manufacturing base with global clout.

Dongguan city, since the 1980s, has become a center for contract manufacturing, producing toys, clothing and electronics for overseas brands. In September 2014, pressured by labor crunch and surging wage bills, Dongguan started to move to an automation, providing subsidies for manufacturers’ “machine for man” programs. For this very reason, manufacturers are facing a shortage of 200,000 workers, even though the city’s minimum salary doubled between 2010 and 2015. It does not only happen in Dongguan, but it’s all around China, the labor pool is shrinking. The former head of the National bureau said that this declining trend will continue until 2030.

Dongguan city center

It’s not only to save costs, automation is also crucial to boost accuracy and quality. Automation has brought down the proportion of substandard products to 5% from 25%. Last January, 1,032 Dongguan companies applied for government subsidies for industrial automation, while accepting more than 10 billion yuan (about 1.53 billion U.S. dollars) for their automation programs. The manufacturers saw productivity up by 65% and costs down by about 10% on average, and their work force is expected to be trimmed by more than 71,000.

How About Human?

Luckily, laid-off workers can easily find new jobs in other factories or the service sector, as job seekers in Dongguan get 1.2 offers on average.

But, worry still fills up workers’ mind. The truth is, based on research on some manufacturers, they hope that industrial automation will help improve workers’ abilities. It is to achieve higher efficiency with the assistance of robots.

“Working hard and working smart sometimes can can be two different things – Byron Dorgan”

Source: Xinhua News